Edge banding glue pot cleaning 7 steps: Keeping Your Edge Bending Machine in Top Shape: A Guide to Cleaning the Glue Port

Edge banding glue pot cleaning 7 steps

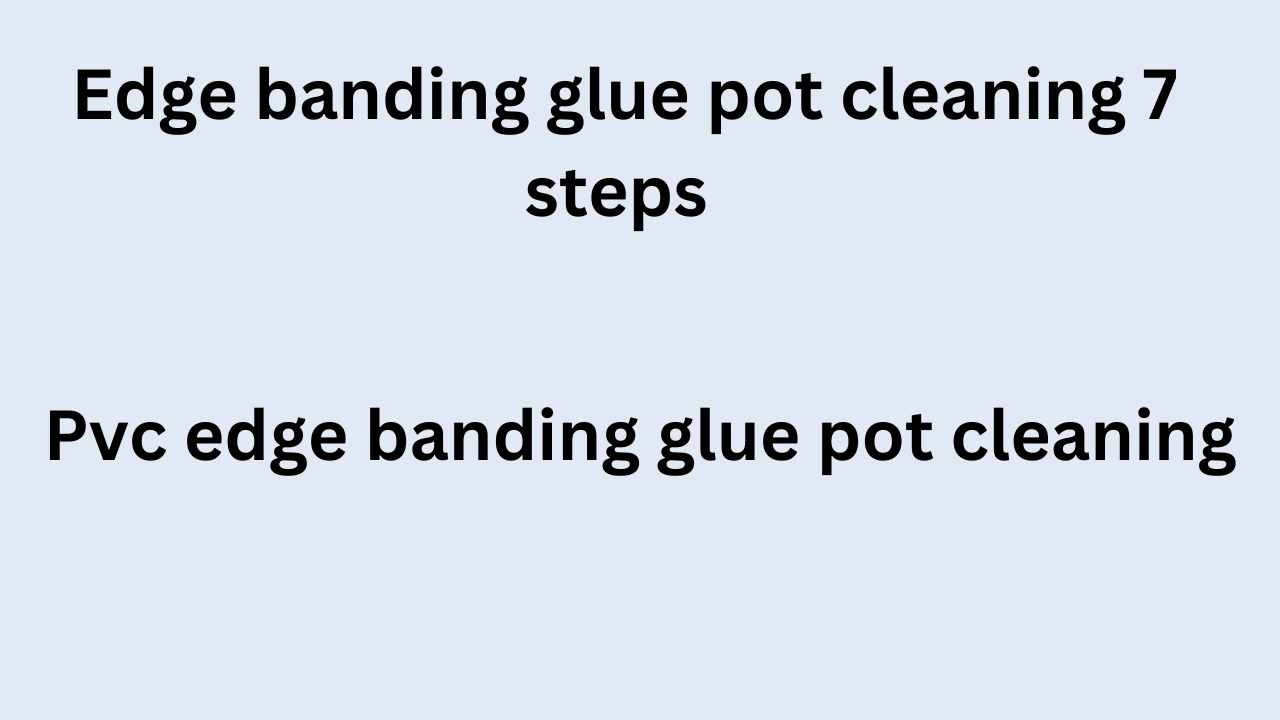

It is critical to clean the glue port of an edge banding machine due to the following considerations. Here’s a step-by-step guide: for Pvc edge banding glue pot cleaning.

- Stop the Machine: It is safety to make sure that the machine is stopped and disconnected from the power source.

- Remove Residual Glue from Edge banding glue pot : Depending on the type of surfaces in contact and how long the port had been bonded unto the hull, there could be some hardened glue; this is removed using a putty knife or scraper. Take care as not to scratch the surface or dig a hole through the material.

- Use Solvent for Pvc edge banding glue pot cleaning : Wipe with a damp cloth using the right solvent for the remaining dirt such as acetone or glue remover. Wipe the area thoroughly.

- Brush Away Debris: Clean around the port using only a soft brush in order to clean the dust or any debris present. A typical one is a small headed, nylon bristled toothbrush, although a soft brush will suffice.

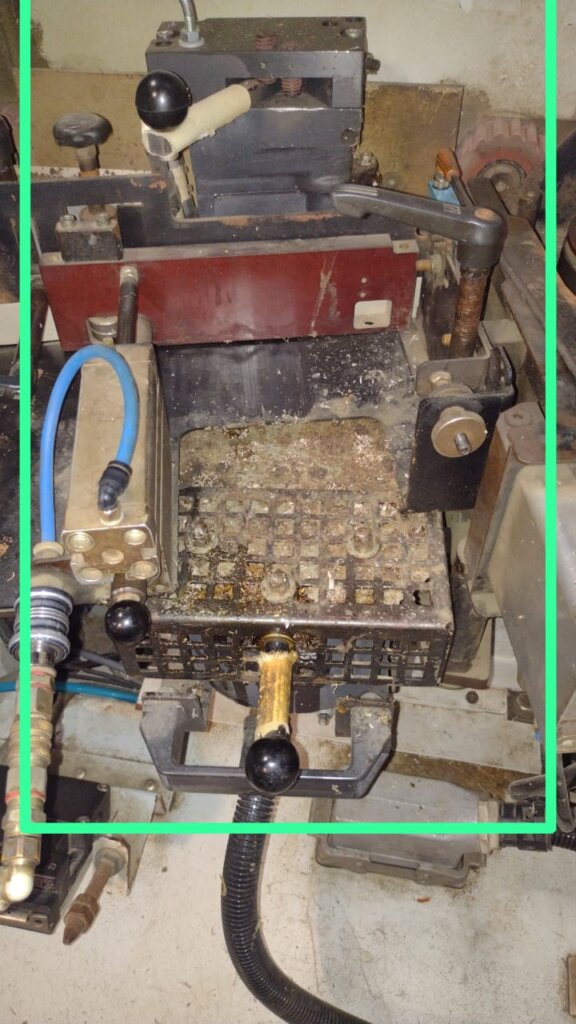

- Inspect the Port after Pvc edge banding glue pot cleaning : Make sure that there are no premature sign of wear or damage on the parts. In the case of wear, replace worn parts as needed The motor of the device should be checked for the wear of the parts that can last for many years before replacement.

- Reassemble Pvc edge banding glue pot cleaning : If you disassembled anything, make sure that they are connected back properly.

- Test the Machine: Cleaning is usually done before the fabric is fed in again through the machine and a test piece runs to check on all the functions. This means that the accumulation is reduced and the proper functioning of the machine is maintained by cleaning regularly.

Edge banding glue pot cleaning 7 steps

- Why Clean the Glue Port?

- Over time, glue residue can accumulate in the glue port, causing several issues:

- Inconsistent Adhesion: Some times, it may lead to poor adhesion caused by residue glue that may be present on the liner and other parts of the application system.

- Machine Performance: Accumulation can actually jam a given port which in turn will lead to a malfunction or non efficient utilization of the existing channels.

- Longevity of the Machine: Service renders equipment usable for a longer period of time. Step-by-Step Cleaning Process

- 1. Safety First Anyone who operates it should remember to switch off and disconnect the machine before starting. As with any kind of equipment, it is extremely important to exercise caution while operating any of the models.

- 2. Gather Your Supplies You’ll need: A putty knife or scraper A clean cloth Solvent (which maybe a acetone or glue remover and others) A soft brush; an old tooth brush would suffice.

- 3. Remove Dried Glue With the putty knife or scraper, the remainder of the hardened glue from the port should be scrape off gently. Use gentle exquisite wash so as not to harm the outer layer of the machine. Take time while removing the glue to ensure that they do not scratch the finish of the surfaces.

- 4. Apply Solvent Moisten a piece of cloth with the solvent you prefer and rub it on the glue spots. Let it sit for a minute or two to get ready for softening the glue.

- 5. Wipe Clean With the damp cloth, clean up the place to drive the softened glue out. This must may require a repetition for some areas that still resist to be washed. Any excess may be gently scraped off with a soft bristled brush.

- 6. Final Check Finally, with another piece of clean cloth, wipe the area to eliminate the remaining solvent on the surface. Check the glue port to see that it is clean and pristine without the least hint of glue on it.

- 7. Reassemble and Test After cleaning it try to fix all the dismantled parts if there were any so that they do not cause any problem in future usage. When all components have been reassembled add power and start up the machine to perform a test part. Regular Maintenance Tips Schedule

- Cleanings: As used, consider establishing lifestyle for cleansing of the glue port. It may be enough to do it on a monthly basis only, for the cases when the vehicle is not used frequently, while for the cases, when it is used frequently, it is recommended to do it daily.

- Monitor Glue Quality: One can minimize on the build-up of residues by investing in high-quality glue.

- Keep the Area Clean: It might also be important from time to time to clean the environment around the edge banding machine so that dust does not affect the glue. Conclusion There are few things as simple as messing up the glue port that is used in an edge banding machine yet it goes a long way in determining the quality of your finished products. Remember, that applying these steps and carrying out regular maintenance procedures, you will always have your machine in proper working condition and will provide perfect edge banding. Happy woodworking!

| Homag :-https://www.homag.com/en/machines/edge-banders-tenoners/edgebanders-and-edge-banding-machines |